Shenzhen Xingtong IOT Technology Co., Ltd.

Barcode Scanner Manufacturer with development & Invention ability

In the wave of intelligent manufacturing and digital transformation of supply chains, product traceability code management has become a core component of enterprise quality control and compliant operations.

However, when a company faces the task of scanning 1 million product traceability codes, the traditional manual operation mode reveals efficiency bottlenecks: a single person scanning one item per second, working 10 hours a day, would require 27 days to complete the entire scanning process, and there are also risks of missed scans and incorrect scans due to human error.

This scenario reflects the limitations of traditional industrial barcode scanning technology – in large-scale production scenarios, inefficient manual operations have become an invisible constraint hindering the release of enterprise productivity.

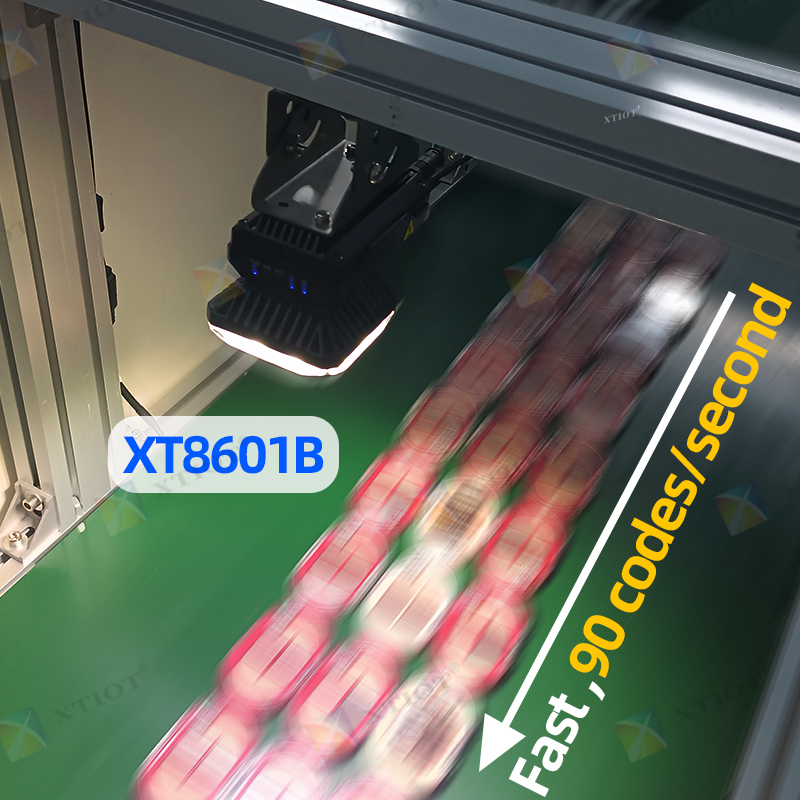

Technological Breakthrough: The Industrial-Grade Design Logic of Xingtong IoT XT8601B

The XT8601B batch barcode scanner launched by Xingtong IoT redefines the technical standards for industrial barcode scanning scenarios through innovative hardware architecture and algorithm optimization. Its core advantages are reflected in three aspects:

Ultra-High Frequency Parallel Scanning Technology

The device is equipped with a customized image sensor and multi-threaded decoding chip, supporting high-frequency triggering 200 times per minute, and each scan can simultaneously identify 100 barcodes. This design breaks through the physical limitations of traditional scanners' "single scan, single item" approach, increasing the data throughput per unit of time by two orders of magnitude.

Intelligent Anti-Interference Algorithm

For common interference factors in industrial environments such as reflection, damage, and dense arrangement, the XT8601B has a built-in adaptive filtering algorithm and deep learning model, which can dynamically adjust exposure parameters and decoding strategies. Actual test data shows that even in extreme scenarios with a barcode density of 5 per square centimeter, the device can still maintain a recognition accuracy of 99.7%.

Industrial-Grade Reliability Design

The all-metal body and IP65 protection rating ensure stable operation of the device in a temperature range of -20℃ to 50℃ and 85% RH humidity, with an MTBF (Mean Time Between Failures) exceeding 50,000 hours. This feature makes it an ideal choice for high-intensity continuous operation scenarios such as automotive manufacturing and 3C electronics. Efficiency Quantification: A Technological Leap from 27 Days to 50 Minutes

Taking a 1 million product scanning task as an example, the technical advantages demonstrated by the XT8601B can be directly translated into business value:

Time Cost Reduction:

The work that traditionally required 27 days can be completed in just 50 minutes with the XT8601B (1 million pieces ÷ (200 scans/minute × 100 pieces/scan)), representing a 7776-fold increase in efficiency.

Optimized Labor Costs:

A single device can replace 30 skilled workers, eliminating the need for companies to invest heavily in training resources and human resource management costs.

Improved Data Reliability:

The device features a built-in verification mechanism and logging system, ensuring that the scanning data for each product is traceable and auditable, meeting the requirements of quality management systems such as ISO 9001.

Technological Empowerment:

Reshaping the Industrial Barcode Scanning Ecosystem

Within the framework of Industry 4.0, the XT8601B is not just a hardware tool, but also an entry point for enterprise digital transformation. It supports multiple protocol interfaces such as TCP/IP and RS-232, allowing for seamless integration with MES, WMS, and other systems, enabling real-time uploading and intelligent analysis of scanning data.

After deployment by a certain automotive parts manufacturer, the efficiency of the production line scanning process increased by 90%, and the inventory counting cycle was shortened from 7 days to 2 hours.