Shenzhen Xingtong IOT Technology Co., Ltd.

Barcode Scanner Manufacturer with development & Invention ability

The automatic code scanning device belongs to the barcode scanning device, which can realize the action of automatically sensing and triggering the scanning of barcodes for data collection, without manual operation. The automatic barcode scanner uses a high-performance barcode reader to solve the problem of barcode automatic detection on the assembly line, and judges the different states of the barcode to control the start and stop of the assembly line, thereby realizing the automation and efficiency of the production line.

Let's explain in detail why we choose automatic code scanning equipment? What are the advantages of using an automated barcode reader?

Why choose automatic code scanning equipment?

The automatic code scanner is mainly used to solve product barcode detection in the production line, print serial numbers in large quantities, barcode label printing enterprises, trademark printing factories, and automatically detect repeated barcodes on the assembly line and judge whether the printed barcodes are correct, whether there are repeated codes, Missing codes, wrong codes and other adverse phenomena, to ensure the integrity of the barcode after the product leaves the factory, to realize barcode printing and detection automation, improve label printing quality and efficiency, reduce barcode label printing errors, and avoid product shipment error costs. In practical applications, the inspector directly inputs the barcode of the product to be inspected, and uses this barcode as the reference barcode for scanning comparison and counting.

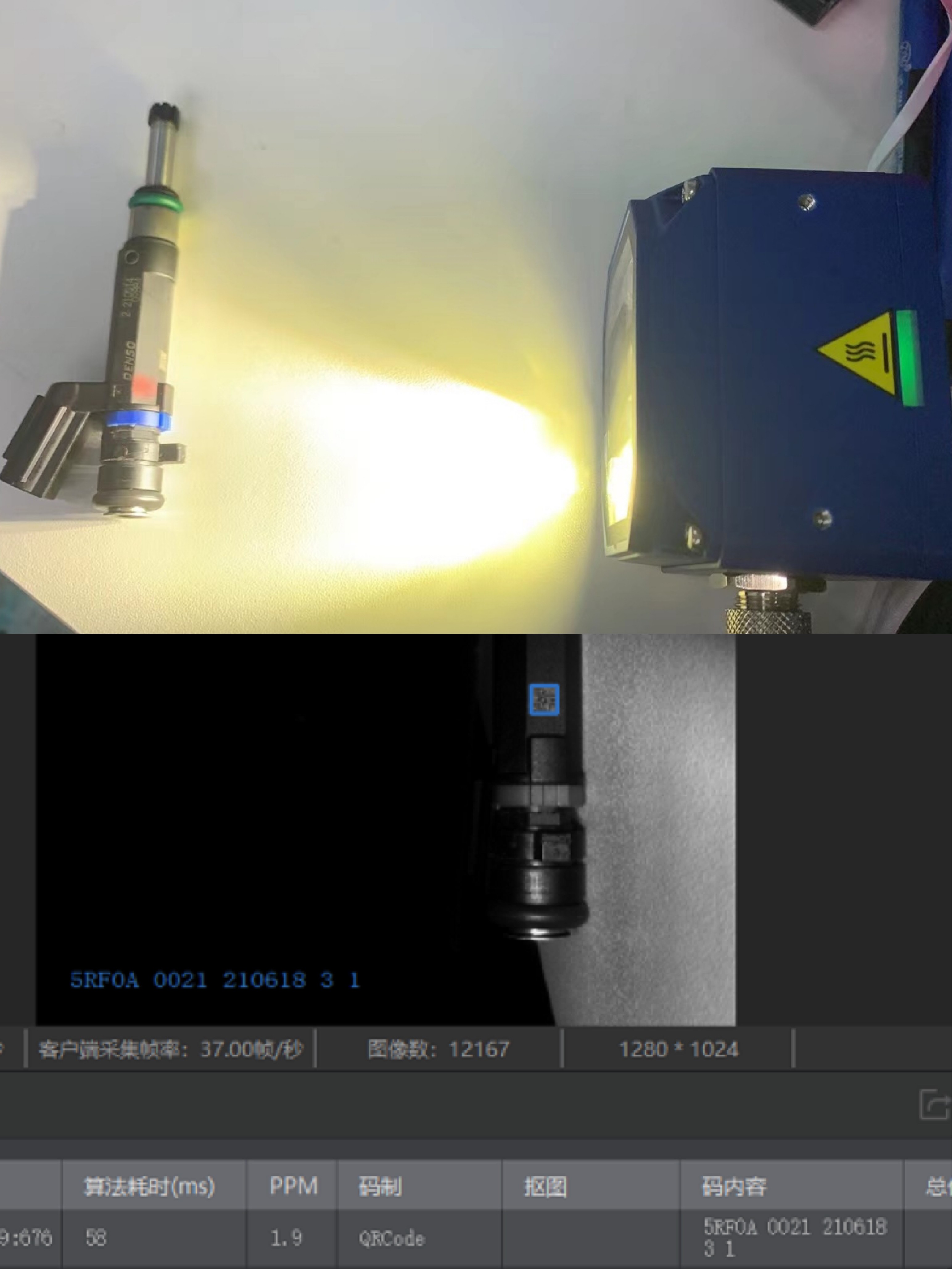

1. Scan code detection is correct

When the product passes through the sensor and the fixed code reader scans and compares correctly, the green indicator light is on, and the correct barcode and time information are recorded;

2. Scan code detection error

When the sensor finds that the fixed code reader has a product barcode that cannot be scanned; the red indicator light is on, and at the same time, the product that cannot read the 2D code is automatically removed from the assembly line; At the same time, an alarm sound will be issued, and the assembly line will automatically stop running immediately; when the product passes through the sensor, but the fixed code reader scans the wrong barcode, the red indicator light will be on, and the product that has read the wrong QR code will be automatically removed from the assembly line. At the same time, the system sends out an alarm sound and automatically stops the assembly line; when the inspector hears the alarm sound, he can quickly deal with it according to the actual situation, stop the product under the assembly line, and record the relevant error barcode information.

What are the advantages of using an automated barcode reader?

1. The use of automatic code scanning equipment can reduce manpower and reduce product production costs;

Significantly increase labor productivity. That is to say, more products can be produced per unit time, and each labor input can create higher output value, and can free workers from conventional manual labor and turn to more creative work;

2. High work efficiency, improve the production efficiency of enterprises, and increase production capacity;

Product quality is highly repeatable and consistent, which can greatly reduce the failure rate;

3. The production process of the whole process is stable, which can effectively improve product quality;

The use of automatic code scanning equipment can effectively improve product consistency and greatly reduce manufacturing costs. The takt time of automatic assembly production of the machine is very short, which can achieve high productivity, and at the same time the machine can run continuously, thus greatly reducing the manufacturing cost under the condition of mass production.

4. It is suitable for mass production, which reduces the production cost of the enterprise and has high product precision;

The automatic code scanning equipment can guarantee the high precision of product assembly and production; shorten the manufacturing cycle and reduce the number of products. Machine automation shortens the manufacturing cycle of products, enables enterprises to achieve fast delivery, improves the competitiveness of enterprises in the market, and at the same time can reduce the quantity of raw materials and products, and reduce the cost of working capital;

5. Reliable automation products are easier to manage than humans, enhancing the company's competitiveness;

Automatic code scanning equipment can replace our manual work, which can greatly reduce costs for enterprises. It replaces manual operation in an environment that is harmful to the human body and dangerous; and in some cases, it can only rely on machine automation for production. At present, the products on the market are becoming more and more miniaturized and miniaturized, the size of parts is greatly reduced, and various micro-electro-mechanical systems are developing rapidly. The manufacture and assembly of these micro-mechanisms, micro-sensors, micro-actuators and other products can only rely on machines to fulfill.