Shenzhen Xingtong IOT Technology Co., Ltd.

Barcode Scanner Manufacturer with development & Invention ability

Although our country's digital reform is in full swing, the digital level of my country's manufacturing industry is generally still relatively low, especially warehousing. With the improvement of social economy and people's consumption level, the production mode of manufacturing enterprises has also changed from small batches to mass customization, and warehouses, as the logistics center of the supply chain, have more and more responsibilities. With the help of the manufacturing warehouse management system, it is particularly important for manufacturing enterprises to respond to the needs of business expansion in a timely manner to create intelligent warehousing.

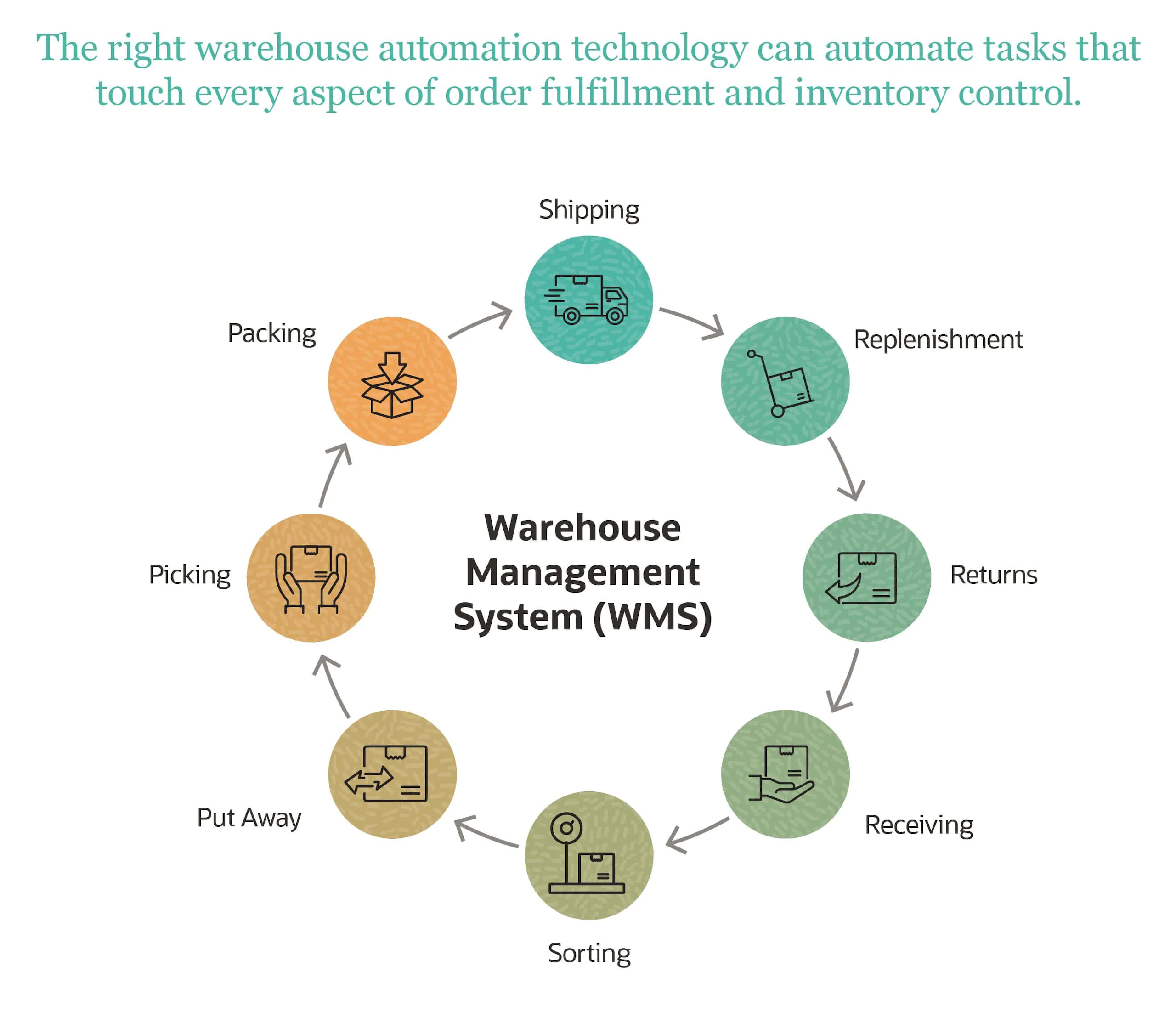

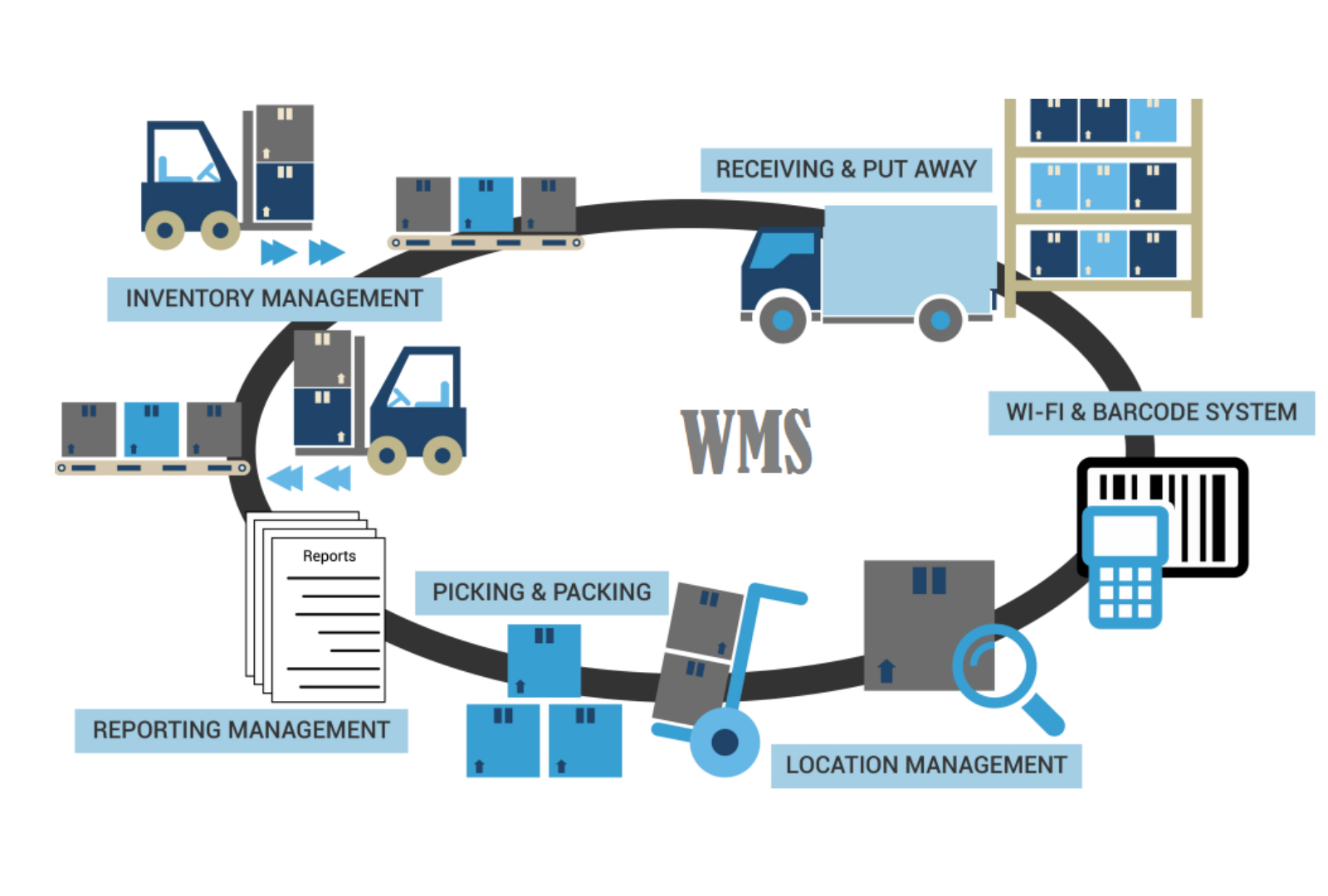

The manufacturing warehouse management system is a computer software that uses barcode technology, database technology and Internet of Things technology to integrate resources and digitally manage and control warehouse goods, personnel, and operating procedures. Through the application of this system, manufacturing enterprises can promote the digital transformation of warehouses and create intelligent warehouses. The specific application effects of the system are as follows:

1. The manufacturing warehouse management system realizes the standardization of warehouse operation process

After using the manufacturing warehouse management system, it will greatly reduce the randomness of employees' operations and realize the standardization of warehouse operation processes. All job tasks and documents are assigned, generated and reviewed by the system. Job operations need to be scanned by PDA. What tasks should be done in each link, and how each task should be done, are all carried out under the control of the system.

2. The manufacturing warehouse management system reduces the workload of personnel

In the past, after the warehouse operation was completed, it was necessary to manually enter the relevant data, which not only increased the workload of employees, but also could not guarantee the real-time and accuracy of the data. With the manufacturing warehouse management system, every time the warehouse operation is completed, the relevant operation data will be automatically updated to the system in real time. In addition, system guidance and PDA scanning operations reduce the requirements for employee experience and literacy, and employees work more efficiently.

3. Manufacturing warehouse management system realizes operation supervision

Before the manufacturing warehouse management system was used, it was very difficult for the warehouse management to supervise the operations on the warehouse site because they could not be on site all the time. After using the manufacturing warehouse management system, it is possible to view the operation progress and actual performance in the system in real time, realize operation supervision, and adjust the management direction in time.

4. The efficient integration of manufacturing warehouse management systems to improve the level of comprehensive management

Generally speaking, manufacturing enterprises usually also have ERP, SRM, MES and other systems. The manufacturing warehouse management system can connect to these systems through interfaces, and realize data sharing through efficient integration, thereby improving the comprehensive management level of the enterprise.

The above is the application effect of the manufacturing warehouse management system. Under the application of the manufacturing warehouse management system, the warehousing operation process, warehousing efficiency and digital management level of manufacturing enterprises will be greatly improved, thus realizing the transformation from traditional warehousing to intelligent warehousing.