Shenzhen Xingtong IOT Technology Co., Ltd.

Barcode Scanner Manufacturer with development & Invention ability

How is the industrial automation fixed scanner applied in the factory assembly line? As we all know, with the sharp rise in labor costs of enterprises, many enterprises have gradually turned their attention to automatic barcode scanners in order to cope with the high human and material costs, and use high-performance barcode readers to solve the problem of automatic barcode detection on the assembly line, and Determine the different states of reading barcodes to control the start and stop of the assembly line, so as to realize the automation and efficiency of the production line. So what role does the industrial barcode scanner play in the factory assembly line in this application?

It is understood that the automatic barcode scanner is mainly used to detect product barcodes in the production line, print serial numbers in large quantities, barcode label printing companies, trademark printing factories, and automatically detect repeated barcodes in the pipeline and judge whether the printed barcodes are correct or not. There are many bad phenomena such as repeated codes, missing codes, wrong codes, etc., to ensure the uniqueness of the barcode after the product leaves the factory, so as to realize the automation of barcode printing and detection, improve the quality and efficiency of label printing, reduce the printing errors of barcode labels, and avoid product shipments. error cost. In practical applications, the inspector directly enters the barcode of the current product to be tested, and scans and compares the barcode based on this barcode, and counts the number.

1. Scan code detection is correct

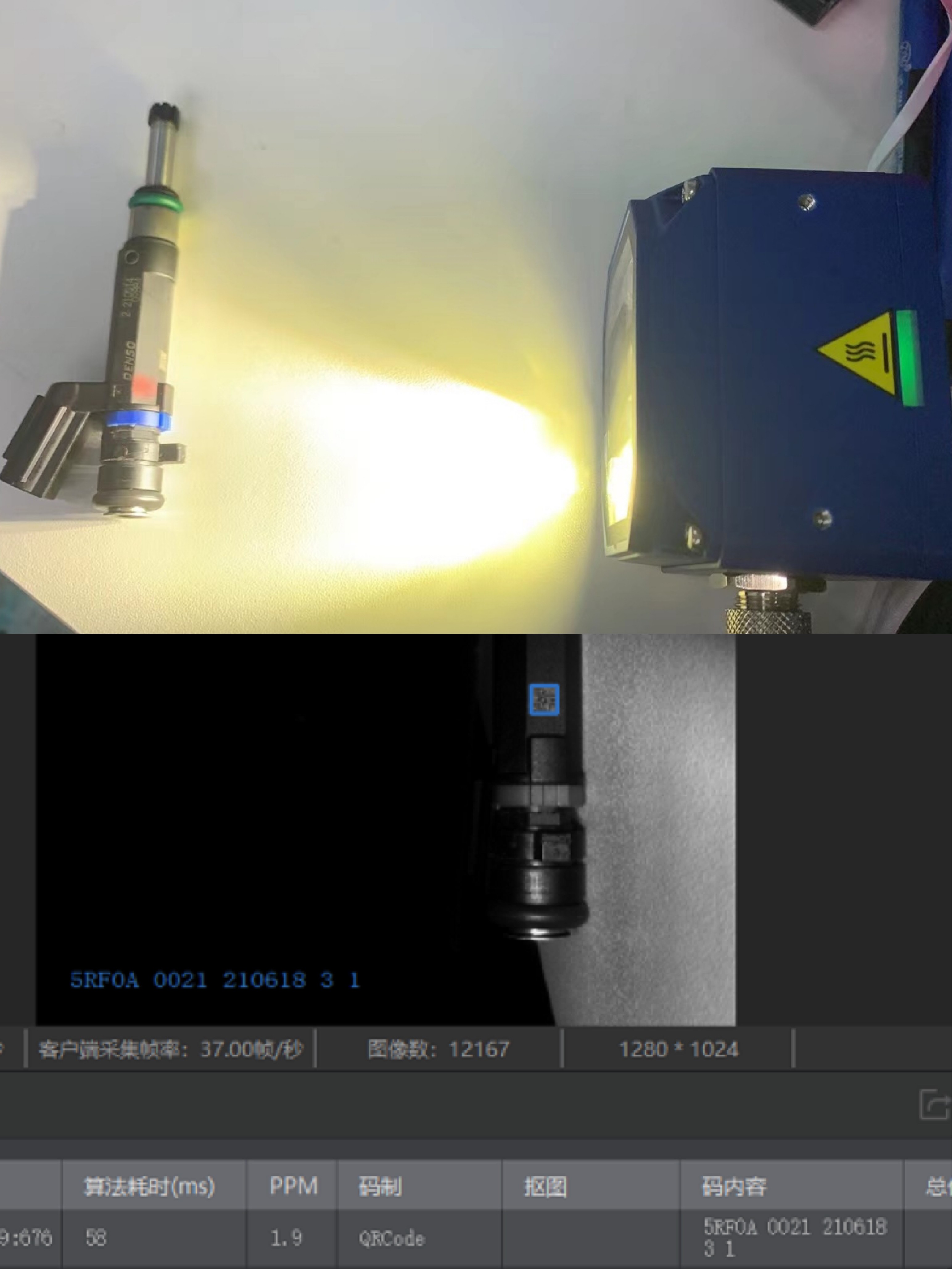

When the product passes the sensor and the fixed barcode reader scans and compares correctly, the indicator light is green, and the correct barcode and time information are recorded.

2. Scan code to detect errors

When the sensor finds that the fixed barcode reader has a product barcode that cannot be scanned, the red indicator light is on, and at the same time, the product that cannot read the QR code will be automatically removed from the assembly line. If this situation occurs three times in a row, the system will sound an alarm and stop running the assembly line automatically when the system fails to perform the above operations. When the product passes the sensor, but the fixed barcode reader scans the wrong barcode, the red indicator light will be on, and automatically The products that read the wrong QR code will be removed from the assembly line, and the system will sound an alarm and automatically stop the assembly line. When the inspector hears the alarm sound, he can quickly deal with the actual situation and stop running the products under the assembly line. And record the relevant error bar code information.

The barcode reader, which plays a central role in the entire factory assembly line, plays a vital role in controlling whether the assembly line starts and stops.