China High-Tech

Enterprises

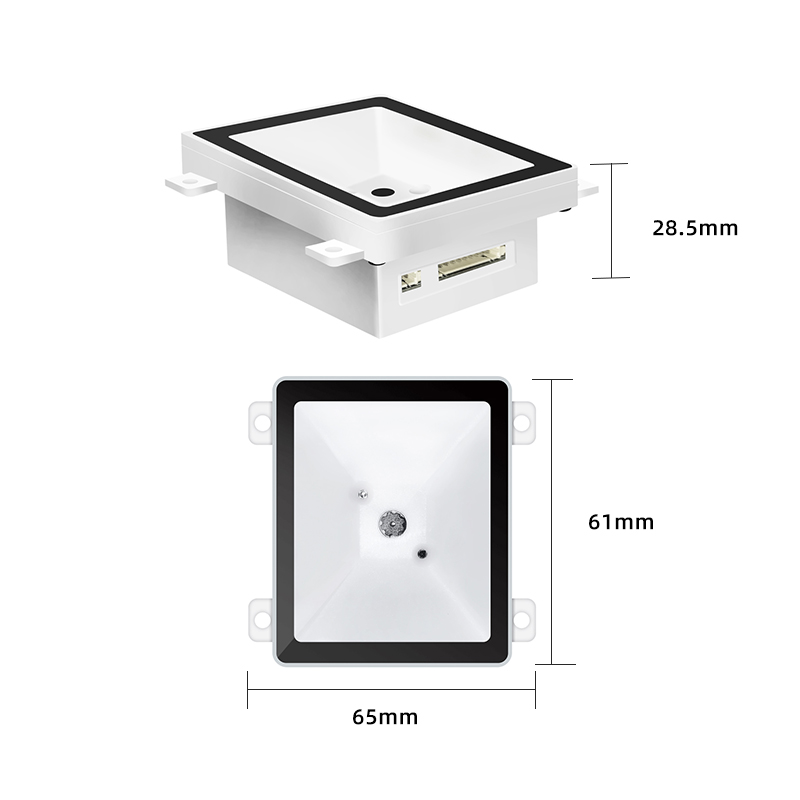

XTIOT China Factory Manufacturer Chinese Suppliers Made in China XT205M2 Integrated Induction Mode UPC-A Serial Interface Barcode Scanner Module

Fixed Mount Barcode Scanner

XT205M2 is fixed mount barcode scanner which suitable for KIOSK, vending machine, wash machine, POS device, etc.

Communication: USB-HID, USB-CDC, USB-HID POS/RS232/TTL/RS485

Compatible System: Android, IOS, Windows, Linux OS, MAC, etc.

Technology: CMOS, 640x480 global shutter image sensor

Decoding Ability: 1D, 2D

Resolution: ≥5mil

Support: serial commands control

Get in touch with us to learn more.

Fixed Mount Barcode Scanner

XT205M2 is fixed mount barcode scanner which suitable for KIOSK, vending machine, wash machine, POS device, etc.

Communication: USB-HID, USB-CDC, USB-HID POS/RS232/TTL/RS485

Compatible System: Android, IOS, Windows, Linux OS, MAC, etc.

Technology: CMOS, 640x480 global shutter image sensor

Decoding Ability: 1D, 2D

Resolution: ≥5mil

Support: serial commands control

Get in touch with us to learn more.

Technical Specifications

| Image Sensor | CMOS |

| DPI(W*H) | 640px*480px |

| Floodlight | White LED |

| 1D | EAN-8, EAN-13, UPC-E, UPC-A,ISBN,ISSN,Code128, UCC/EAN-128, AIM-128,Code 39, Code 93, Code 11, Codabar,Interleaved 2 of 5, ITF-6, ITF-14, Matrix 2 of 5,Industrial 25, Standard 25,Plessey, MSI-Plessey, GS1-DataBar (RSS), (RSS-14, RSS- Limited,RSS-Expand) |

| 2D | PDF417, Data Matrix, QR, Micro QR |

| Accuracy | ≥3mil |

| Contrast Ratio | ≥20% |

| 1D:EAN-13 | (13mil) 25-110mm |

| 2D:QR Code | (15mil) 0-90mm |

| PDF 417 | (6.7mil) 35-45mm |

| Data Matrix | (10mil) 30-50mm |

| Tilt | ±60°@ 0°Roll and 0°Skew |

| Rotate | 360°@ 0°Pitch and 0° Skew |

| Deflection | ±60°@ 0°Roll and 0° Pitch |

| Field of View Angle | Horizontal:68° Vertical:51° Diagonal: 84.8° |

| Setting Method | 1. Setting barcode 2. Serial Command |

| Prompt Mode | Beep、LED indicator |

| Data Interface | USB KBW、USB HID-POS、USB CDCTTL、RS 232、RS 485 |

| Working Voltage | 5VDC±5% |

| Working Electric Current | 280mA |

| Standby Electric Current | 230mA |

| Working Temperature | -20℃~+60℃ |

| Storage Temperature | -40℃~+70℃ |

| Relative Humidity | 5%~95% (No condensation) |

Actual Use Cases

Case 1: Retail Store Self-Checkout System

Background:

A retail store wanted to improve the efficiency of its self-checkout system, reduce customer waiting time, and ensure the accuracy and timeliness of product information.

Solution:

The retail store used the XT205M2 Tab communication port to support serial command trigger scanning mode barcode scanner module provided by China factory manufacturer XTIOT, which was integrated into the self-checkout system for quick entry of product barcode information.

Implementation steps:

Hardware installation: Install the XT205M2 barcode scanner module at key locations of the self-checkout machine.

Software integration: Connect the scanner module to the checkout system through the Tab communication port and configure it to support serial command trigger scanning mode.

System testing: Conduct comprehensive functional tests to ensure that the scanner module can accurately read product barcodes and support manual trigger scanning.

User guide: Create a simple operation guide to help customers understand how to use the scanner module for self-checkout.

Effect:

Improve efficiency: Manual trigger scanning reduces customer waiting time.

Reduce errors: Accurate product barcode reading reduces input errors.

User experience: The plug-and-play design simplifies the customer's operation process.

Real-time update: Scan data is uploaded to the backend management system in real time, which is convenient for inventory monitoring and data analysis.

Case 2: Fast Prescription Processing in Hospital Pharmacies

Background:

A hospital pharmacy needs to improve its prescription processing efficiency, ensure that patients can quickly get medicine, and ensure the accuracy and timeliness of prescription information.

Solution:

The hospital pharmacy uses the XT205M2 Tab communication port to support serial command trigger scanning mode barcode scanner module provided by Chinese factory manufacturer XTIOT, which is integrated into the prescription processing system for fast entry of prescription information.

Implementation steps:

Hardware installation: Install the XT205M2 barcode scanner module at key locations in the pharmacy.

Software integration: Connect the scanner module to the prescription processing system through the Tab communication port and configure it to support serial command trigger scanning mode.

System testing: Conduct comprehensive functional tests to ensure that the scanner module can accurately read prescription information and support manual trigger scanning.

Staff training: Provide operation training for pharmacy staff to ensure that they can correctly use the barcode scanner module for prescription processing.

Effect:

Improve efficiency: Manually triggered scanning reduces patient waiting time.

Reduce errors: Accurate reading of prescription information reduces input errors.

User experience: Plug-and-play design simplifies the operation process for staff.

Real-time update: Scan data is uploaded to the backend management system in real time, which facilitates prescription monitoring and data analysis.