Shenzhen Xingtong IOT Technology Co., Ltd.

Barcode Scanner Manufacturer with development & Invention ability

In today's barcode traceability systems, problems such as duplicate codes, missing codes, multiple codes, no codes, incorrect codes, damaged codes, and mixed batches have consistently plagued product shipment quality. While small quantities can be manually scanned and compared one by one, what about large quantities?

Below, we'll compare the difference between traditional manual scanning and the Xingtong batch barcode scanning system using a single order of 1 million items: Assuming a worker scans one item per second, even if they work 10 hours a day without breaks, they can only scan 36,000 items, requiring 27 days to complete the 1 million item scanning task! This not only requires a large number of workers working in shifts but also easily leads to missed or incorrect scans due to fatigue, resulting in chaotic traceability data and increased rework costs; if incorrect products reach the customer, it will lead to customer complaints and even order loss!

The Xingtong IoT barcode comparison system uses an integrated software and hardware design. For the same 1 million products, this system can scan up to 86 codes per second, completing the entire scanning task in 3.5 hours, with accurate and reliable key data! From 27 days to 3.5 hours, efficiency is increased by over 185 times, completely eliminating the need for long hours of overtime. The Xingtong barcode comparison system also supports simultaneous scanning of entire boxes, further significantly increasing efficiency!

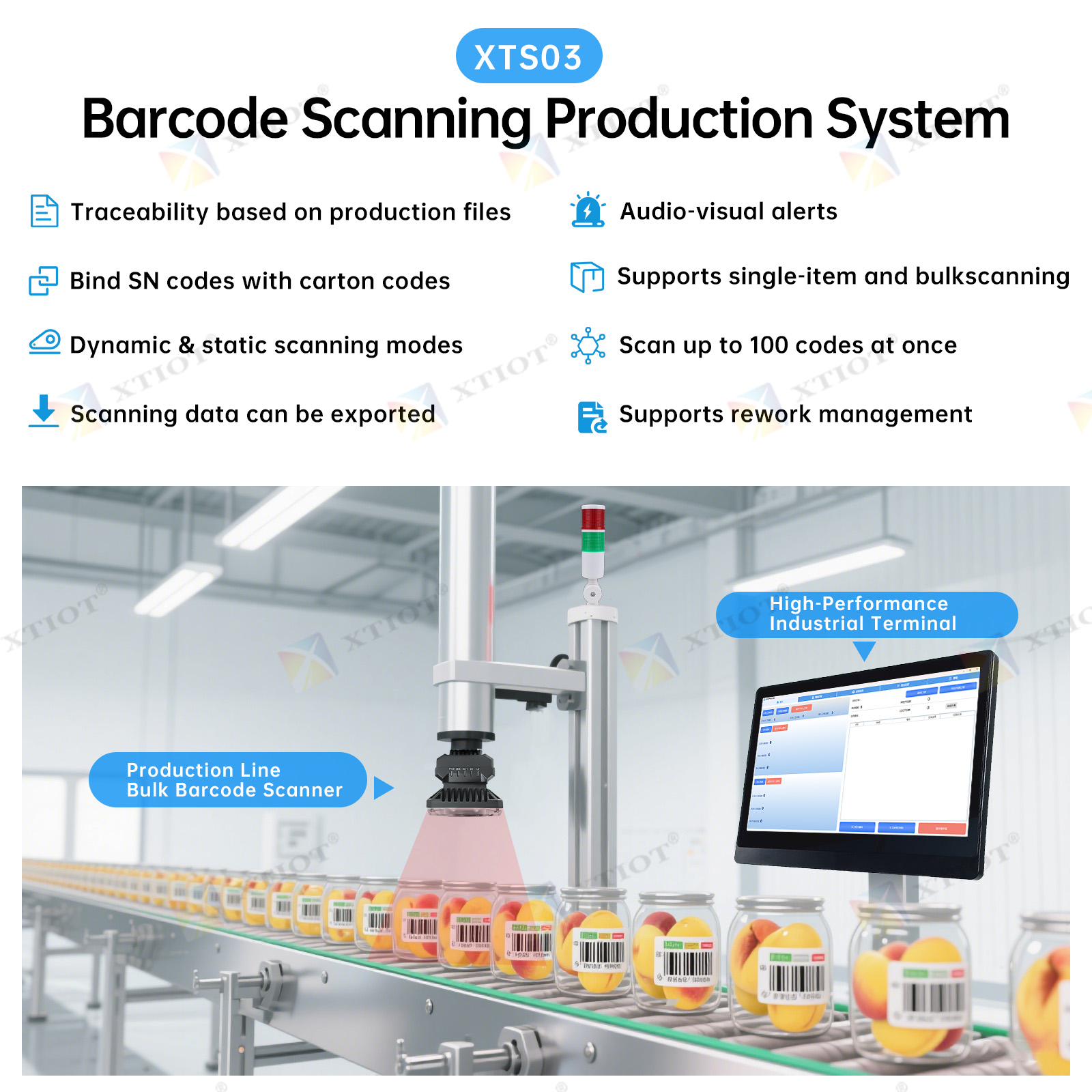

Features of the Xingtong IoT Barcode Comparison System:

1. Integrated software and hardware design, eliminating compatibility issues and blame-shifting between different manufacturers' products.

2. Software: Scans according to preset rules; if a mismatch is detected, it triggers an audible and visual alarm and automatically stops the line to remove the defective product.

3. Hardware: Industrial control all-in-one machine XT802F with a 15.6-inch multi-touch screen, high-definition visualization, unaffected by glove operation, 16GB+512GB large memory, and high-speed operation without lag. Multiple expansion interfaces facilitate connection to external devices.

4. Industrial barcode scanner: Depending on the actual product needs, industrial barcode scanners ranging from 6 million to 20 million pixels can be selected, with 3mil accuracy, capable of scanning minimum 1*1mm QR codes; the maximum conveyor line speed can reach 90 codes/second, and up to 200 codes can be scanned simultaneously in a single pass. It can be used with both high-speed production lines and full-pallet or full-case scanning systems.