Shenzhen Xingtong IOT Technology Co., Ltd.

Barcode Scanner Manufacturer with development & Invention ability

With the continuous development of Internet of Things technology, the internationalization of product circulation, the requirements for product traceability and product regional protection will become more and more stringent.

Under this circumstance, XTIOT Technology, which has 20 years of industry experience in the field of barcode automatic identification technology, has launched a set of highly cost-effective and widely used production line barcode system solutions. Through the barcode system, customers can It can better see some situations in the production process, and at the same time help enterprises to achieve zero errors for standard products, and better control the error rate of products in the production process.

Overview of the production line barcode system solution:

In the automated assembly line and each processing process, the main components are labeled with barcodes, and the barcode information is collected and entered into the database of the computer server through a fixed scanner, that is, a barcode reading device. With a unique barcode, no matter where the product is shipped, it will be recorded. If there is a quality problem, you only need to read the barcode on the warranty card, you can call up the relevant information of the product in the database, which facilitates the quality tracking and after-sales service of the product.

Customer Benefits

1. Quality tracking:

By recording and tracking the production site, production date, team production line, PCB version number, batch number, serial number, quantity and time of each link of production materials, operator machine number, etc. Traceability - from the finished product back to the raw materials used.

2. Material cost control:

Establish a unique number for all production raw materials used, attach barcode labels, and establish strict picking control. Through each type of product bill of materials, the product production plan can be decomposed into a material plan, and the material surplus can be calculated reasonably, and the deviation of the material consumption of each batch of products from the standard finished product can be controlled.

3. Working time control:

By scanner the operator number, machine number, and recording the working time of each operator, after statistical analysis, the deviation between the working time of unbatched products and the standard working time can be calculated.

4. Production Statistics:

By scanner the finished product body number and the barcode of each main component, the output statistics of the finished products, the statistics of the materials used, and the waste situation can be calculated automatically.

5. Piece statistics:

Many enterprises adopt piece-rate wage method, and piece-rate statistics is a very cumbersome task. Through the barcode identification and production work sheet on each product, it is easy to count the number of products completed by each worker, and to investigate the number of defective products. Responsible person.

6. Production scheduling:

Manage online production tasks, orders, batches, work orders, etc., and can modify the schedule according to specific conditions.

7. Product Archives:

Using the barcode data acquisition terminal, it is possible to build a complete product file including detailed information about the product's manufacturing process, component configuration, and quality inspection data.

8. Process data query:

Using barcode technology, various basic consultations are stored in the ERP system, and business data is collected from the production line in real time, which ensures the real-time nature of consultation. And because the consultation comes from the entire production site, all processes such as raw material, processing, assembly, quality inspection, maintenance, packaging, storage, etc., ensure the comprehensiveness and accuracy of the consultation.

Product Recommendation: Stationary Scanner XT816

.jpg)

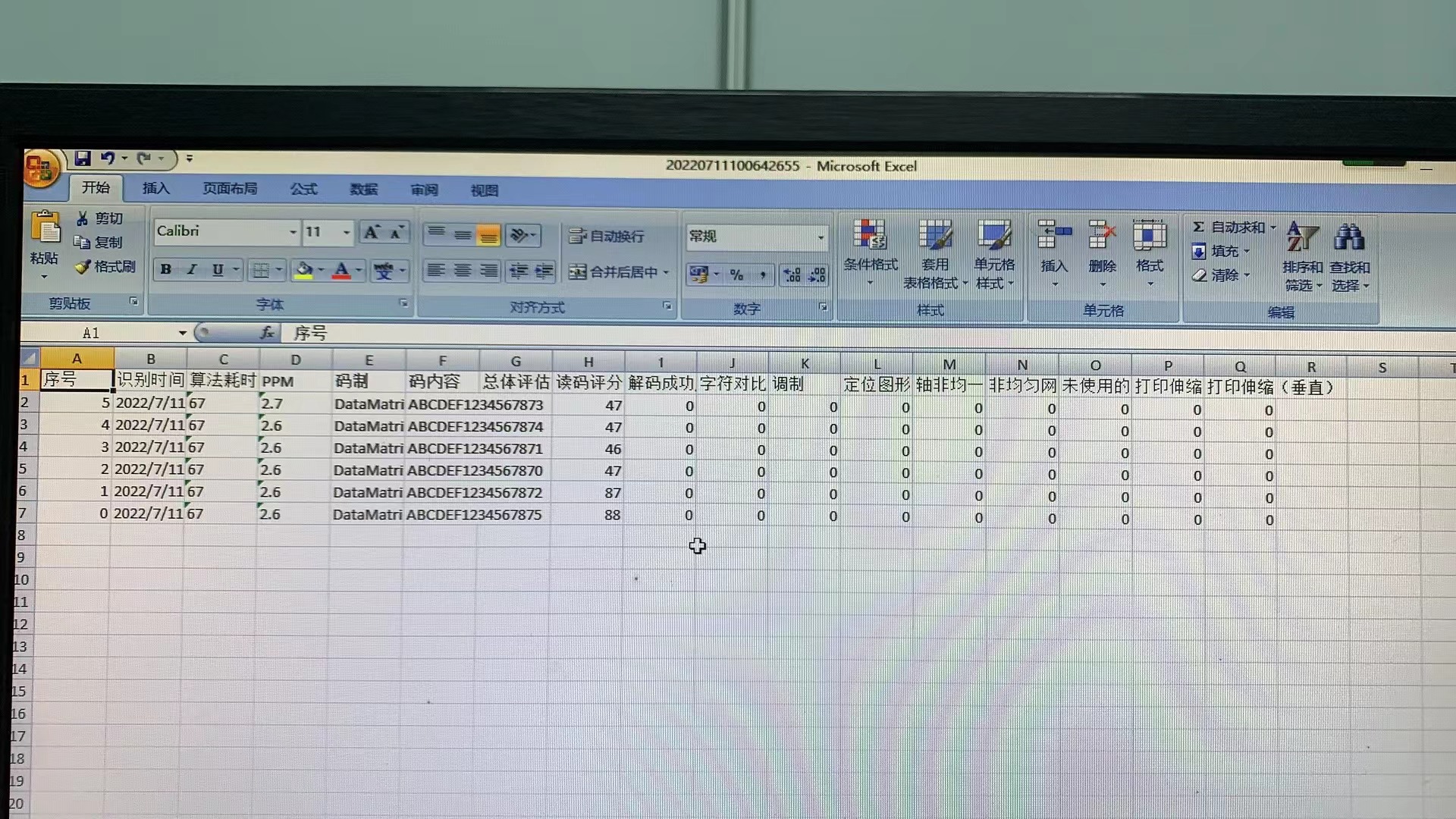

The XT816 stationary scanner is a stationary barcode reading device specially customized for OEMs in industrial fields such as sorting lines, conveyor belts and production lines. In the application of automatic barcode scanner in production lines, XT816 can be used to automatically enter barcode serial numbers in the production, assembly, testing and other links of the production line, and connect with the barcode scanner automatic detection system to check duplicate codes, missing codes or less codes. Code detection and judgment to ensure zero barcode errors and production line automation after products are out of the market. If you have the need for a program or barcode scanner equipment.